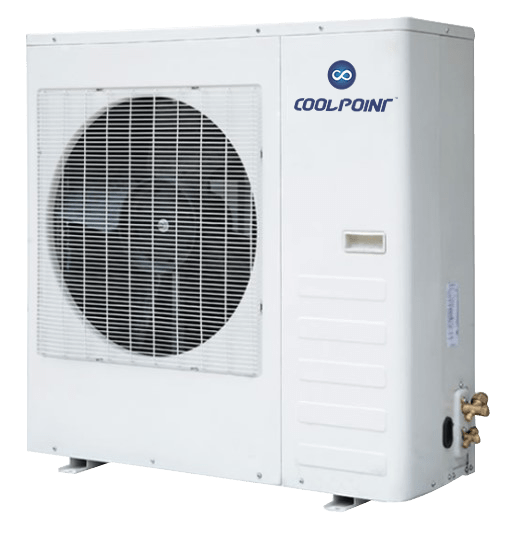

COOLPOINT Condensing Units are designed and manufactured especially for use in systems with indoor units connected to remote condensing units located outdoors. The feature of the CWCU is the extreme flexibility available with COOLPOINT in modifying and adapting these condensing units to meet almost any application requirement for a DX split system in this size range.

CWCU are rated as per principle of ARI 365/94 and ARI 210 240/94 standards.